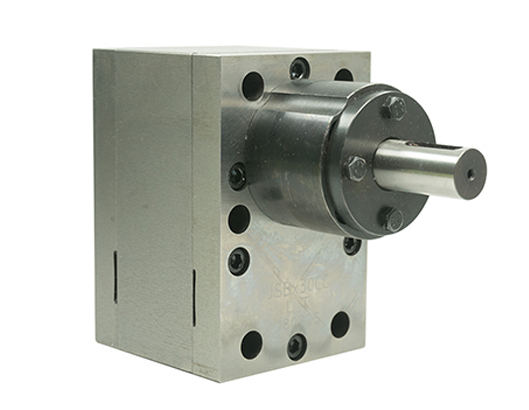

Chemical Gear Metering Pump Selection

Email: sales01@cxflowmeter.com

WhatsApp: 008618049841995

Chemical Gear Metering Pump Selection

To address the customer's need to deliver solutions with two different pH values, and considering the material properties, flow matching,

and structural optimization requirements of gear metering pumps, the following selection scheme is recommended:

I. Material Selection: Core Adaptation Based on Solution pH

Solution A (Melamine-Urea-Formaldehyde Condensate, pH 9.5±3)

Recommended Material: 9Cr18 (Martensitic Stainless Steel)

9Cr18 contains 18% chromium and 0.95% carbon, is resistant to neutral to weakly alkaline corrosion, and is suitable for environments with

pH 6-12.

This material has high hardness (HRC≥58) and strong wear resistance, capable of handling the potential abrasion from solid particles in

Solution A.

It is less expensive than Hastelloy or titanium alloys, making it suitable for scenarios with limited budgets but requiring corrosion

resistance.

Solution B (Formic acid mixture, pH 1-2)

Recommended Material: Stellite Alloy

Stellite 6B (cobalt-based alloy) contains 28% chromium and 5% tungsten, and is resistant to strong acids (such as sulfuric acid and

hydrochloric acid), especially suitable for extremely acidic environments with pH < 2.

Compared to 316L stainless steel (resistant to pH ≥ 3), Stellite alloy reduces the corrosion rate by more than 80% at pH 1-2, extending

pump life.

If budget is limited, duplex stainless steel (such as 2205) can be considered, but its acid resistance under actual operating conditions

needs to be verified.

II. Flow Matching: Displacement Calculation Based on Solution Viscosity

Solution A Viscosity (2000-10000 mPa·s)

High-viscosity fluids require low-speed operation to reduce shear forces and avoid damaging the solution structure.

Recommended Displacement: 12CC

Calculation Example: If the system requires a flow rate of 30L/min and a drive speed of 1500r/min, then the pump displacement

must be ≥20mL/r (30×1000÷1500).

A 12CC pump can output 6L/min at low speeds (e.g., 500r/min). High flow rate requirements can be met by parallel operation of

multiple pumps or frequency converter speed regulation, while reducing wear.

Solution B Viscosity (1500-6000 mPa·s) Medium-viscosity fluids require a balance between flow rate and efficiency.

Recommended Displacement: 6CC

If the system requires a flow rate of 15L/min and a drive speed of 2500r/min, then the pump displacement must be ≥6mL/r (15×1000÷2500).

A 6CC pump can stably output 6-12L/min within the range of 1000-2000r/min, adapting to viscosity fluctuations.

III. Structural Optimization: Designed for High Viscosity and Corrosiveness

Gear Type Selection

Solution A: Utilizes arc-shaped gears, minimizing meshing impact and reducing wear rate by 40% compared to involute gears, suitable for

solutions containing solid particles.

Solution B: Utilizes involute gears, offering high machining precision (tooth surface roughness Ra≤0.4μm), reducing electrochemical

corrosion in acidic media.

Upgraded Sealing Method

Solution A: Employs fluororubber (FKM) seals, temperature resistant up to 150℃, resistant to melamine-formaldehyde condensate chemical

corrosion.

Solution B: Employs polytetrafluoroethylene (PTFE) seals, resistant to strong acids (pH<1) and possessing strong self-lubricating properties,

reducing friction.

Enhanced Corrosion Resistance with Coating

Solution A: Internally coated with a ceramic coating (e.g., alumina), hardness HV 1200-1500, resistant to particle scratches.

Solution B: Internally plated with a tungsten alloy (W-Co-Cr), resistant to acid corrosion rate <0.01mm/year, extending service life.

IV. Summary of Selection Schemes

Solution Type | Recommended Material | Recommended Displacement | Gear Type | Sealing Method | Coating Treatment

Solution A (pH 9.5) | 9Cr18 | 12CC | Arc-shaped Gear | Fluororubber (FKM) | Ceramic Coating (Alumina)

Solution B (pH 1-2) | Stellite Alloy | 6CC | Involute Gear | Polytetrafluoroethylene (PTFE) | Tungsten Alloy Coating

V. Additional Suggestions

Drive Matching: The motor speed must be compatible with the pump's rated speed (1000-3000 r/min) to avoid accelerated wear due to

high speed (>3000 r/min).

Filtration System: Install an 80-mesh filter at the suction port and a 10μm filter element at the return port to reduce impurities and damage

to the pump.

Temperature Control: Solution A should be kept below 60℃ to avoid a sudden increase in viscosity; Solution B should be kept above 20℃

to prevent formic acid crystallization.

By selecting the above options, the gear metering pump can achieve high precision (error < 0.5%), long service life (> 10,000 hours),

and low maintenance costs under two extreme operating conditions, meeting the needs of chemical production.

If you would like to know more about the specific selection and pricing of gear metering pumps, please contact CIXIFM Winny:

VIEW MORE