wax micro flow sensor

email: porter@microflowmeter.com Shanghai JSNMicro Flow Meter CO.,LTD has a high-tech talent team who have long been engagedin the design, development, installation and commissioning of automatic controlresearch, and have provided satisfactory sets of systems for variousindustries. With a strong professional team,accumulated a wealth of technology, management experience, covering thecountry"s marketing network and branches, can provide users with fast andconvenient technical services. Since JSN Micro Flow Meter establishment, itrely on Siemens engineer’s powerful technology and high-quality service toquickly gain a good reputation in the instrumentation market. Main products:mircoflow meter,oval gear flow meter , electromagnetic flow meter,piston flowmeter,spur gear flow meter,gear pump,gear metering pump. Adhering to the"build Flow Meter’s aircraft carrier, contribute to China"s automationindustry.

wax micro flow sensor

Withthe development of society, the state pays more and more attention to theprocess automation instrumentation industry. However, the Oval gear flow meter industryhas been in a vacancy and has been monopolized by major foreign brands such asMax, KRACHT, OVAL, etc. , People have long endured the expensive, longdelivery, the sale can not be resolved in time and so on, such as semiconductorchip cutting a set of equipment on the millions, once the instrument problems,loss unimaginable, the slayer saw these phenomena, Resolutely resigned assenior engineer in the position of Siemens, the establishment of ShanghaiJi-sheng Instruments Co., Ltd., with great concentration on research anddevelopment of gear flow meter. We have Oval gear flow meter has been awarded anumber of certificates, it is no exaggeration to say that Qishen production Ovalgear flow meter For example, many customers replace the OVAL LSF40 with ourCX-M5-AL because it costs less than half of the LSF40, but has twice the rangethan it does and has the same accuracy.

TheCX-M and G-series mirco flow meters are the world"s new volumetric flowmetersintroduced by BASF in 2011. Since its establishment, the CX-M oval gear flowmeter and the G-series mirco flow meters have been selling well in the marketfor more than 100,000 units a year since they were sold. The third generationlaunched in 2017, with more than 90% accuracy and stability, won thecertification of the National Bureau of Metrology. The quality and reliabilityof Shanghai JiShen instruments need not worry. According to the statistics ofChina Instrument Association, Deep flow meter reliability has always beenranked in the top 3, especially in the long-term statistics failure rate is farbelow the industry average, deep advocate "the best after-sales service isno service", but also achieved a continuous three years without qualitycomplaints .

wax micro flow sensor

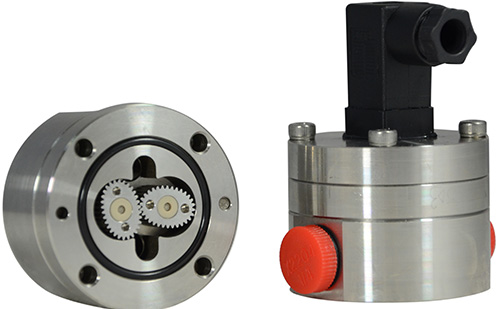

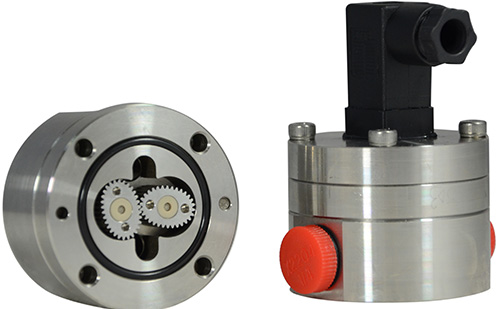

The Ovalgear flow meter is composed of a flow transmitter and a counting mechanism. Themain part of the transmitter consists of a measuring chamber equipped with apair of gear rotors and a sealing coupling. The counting mechanism consists ofa speed reducing mechanism, a precision adjusting mechanism, a counter and apower Pulse transmitter and other components.

wax micro flow sensor

Maintechnical data of JSN micro oval Oval gear flow meter

CX-M2,flow range :0.5~150ml/min,accuracy 0.5%,G1/8"

CX-M3, flowrange:3~300ml/min,accuracy 0.5%,G1/8"

CX-M5, flowrange:5~1000ml/min,accuracy 0.5%,G1/8"

CX-M6, flowrange:0.5~100L/H,accuracy 0.5%,G1/4"

CX-M9, flowrange:6~600L/H,accuracy 0.5%,G1/4"

CX-M12,flow range:0.3~30L/Min, accuracy 0.5%,G1/2"

CX-M25,flow range:0.5~100L/Min, accuracy 0.5%,G1"

What are the precautions for the gear flow meter?

1) In the field installation, it should be noted that the direction of the arrow on the flow meter housing is consistent with the flow direction of the fluid;

2) The flowmeter is installed on the same pipe with the same nominal internal diameter as the inlet and outlet fittings. When the pipe is connected with the flowmeter, the seal should not protrude into the fluid;

3) The fluid to be measured shall be filled with the metering room of the flowmeter and the connecting pipes before and after it. If the fluid to be measured contains gas, a gas separator shall be installed before the flowmeter and the filter;