sodium hydroxide micro flow meter

email: porter@microflowmeter.com Shanghai JSNMicro Flow Meter CO.,LTD.is a family company and it has more than 30 yearshistory. We are specialized in research of high quality flow meters, such as mircoflow meter,oval gear flow meter ,coriolis mass flow meter,electromagnetic flowmeter,piston flow meter, spur gear flow meter,gear pump,gear metering pump andso on. We devote ourselves to break the technology monopoly of foreigncountries. Our micro flow meter can replace Kracht, OVAL, SIKA and OMAGEforeign brands and so on. We have export our flow meters into more than 100countries and Shanghai JSN Micro Flow Meter CO.,LTD has already been a famous Automationinstrumentation company.

sodium hydroxide micro flow meter

Withthe development of society, the state pays more and more attention to theprocess automation instrumentation industry. However, the Oval gear flow meter industryhas been in a vacancy and has been monopolized by major foreign brands such asMax, KRACHT, OVAL, etc. , People have long endured the expensive, longdelivery, the sale can not be resolved in time and so on, such as semiconductorchip cutting a set of equipment on the millions, once the instrument problems,loss unimaginable, the slayer saw these phenomena, Resolutely resigned assenior engineer in the position of Siemens, the establishment of ShanghaiJi-sheng Instruments Co., Ltd., with great concentration on research anddevelopment of gear flow meter. We have Oval gear flow meter has been awarded anumber of certificates, it is no exaggeration to say that Qishen production Ovalgear flow meter For example, many customers replace the OVAL LSF40 with ourCX-M5-AL because it costs less than half of the LSF40, but has twice the rangethan it does and has the same accuracy.

SinceMay 23, 2011, Shanghai Jinshen Instrument Co., Ltd. successfully released a newoval gear flow meter CX-M and G series, the liquid flowmeter range than thefirst in China reached more than 1: 100, and at the same time to ensureaccuracy 0.5% above the flowmeter industry model.From this since the base meterhas been a pioneer in flowmeter technology, but also one of the high-endflowmeter brand.The perfect technical level, excellent quality standards,innovation has been innovation Wells said. Deep base flow meter has been toprovide customers with a reliable use of the experience in the past rely on theimport of the era, the customer has been a headache for after-sales service,and base deep flow meter with 8 years of use of the long life, in one fellswoop cracked this situation.

sodium hydroxide micro flow meter

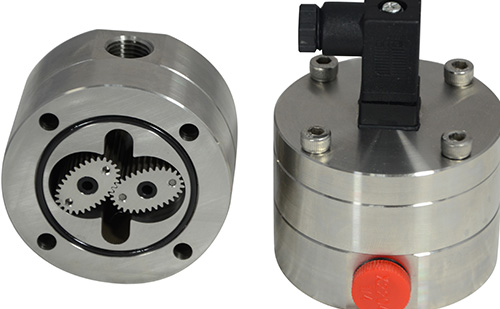

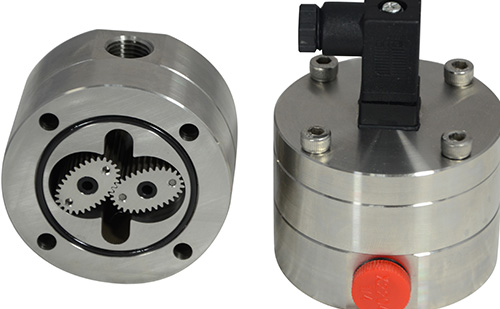

Componentsand principles of the Oval gear flow meter - The measurement part of the flowmeter consists of two intermeshing gears and its housing (metering chamber).The measured medium mass per revolution of the gear is half-moon-shaped 4times, in the mirco flow meter hemispherical volume under certain conditions,as long as the measured gear rotation speed n, we can know the measured mediumflow.

sodium hydroxide micro flow meter

Maintechnical data of JSN micro oval Oval gear flow meter

CX-M2,flow range :0.5~150ml/min,accuracy 0.5%,G1/8"

CX-M3, flowrange:3~300ml/min,accuracy 0.5%,G1/8"

CX-M5, flowrange:5~1000ml/min,accuracy 0.5%,G1/8"

CX-M6, flowrange:0.5~100L/H,accuracy 0.5%,G1/4"

CX-M9, flowrange:6~600L/H,accuracy 0.5%,G1/4"

CX-M12,flow range:0.3~30L/Min, accuracy 0.5%,G1/2"

CX-M25,flow range:0.5~100L/Min, accuracy 0.5%,G1"

What are the precautions for the gear flow meter?

1) When the flow exceeds the specified maximum flow rate, the Oval gear flow meter wear increases with the increase of the rotation speed, and the pressure loss increases sharply, should be avoided. Less than the minimum flow, although still able to measure, but the error increases. Flow meter The starting flow is about 2% of the maximum flow, and the normal working flow is preferably 70%-80% of the maximum flow.

2) Deep-rooted flowmeter is used with various viscosity media from 0.3 ~ 100000cps, different viscosity media will affect the range, the following single must be noted

3) The measured liquid temperature should not exceed the specified value, otherwise, the instrument can not work properly, or even stuck, the counter part is easily damaged at high temperatures. Liquid temperature changes will also cause additional errors in viscosity.