paints mini flow meter

email: porter@microflowmeter.com Shanghai JSN Micro Flow Meter CO.,LTD, research andproduce electromagnetic flow meter, Super Micro Liquid Flow Meter,Ovalgear flow meter ,Mass Flow Meter,Circle Spur Gear Flow Meter,Gear Pump,Gearmetering Pump etc for about 10 years.“JSN trademark and top tenproducts” have won ISO9001, CE, SGS international qualitysystem certification. As the backbone enterprise of China"s automationinstrumentation, it currently supports more than 3,000 companies across thecountry, especially road construction equipment, asphalt mixing stations, roadfuel injection, grouting, polyurethane, dispensing, hot-melt adhesives andother mechanical equipment and automation. Application occasions. Our factoryhas independent CNC machining center, gear carbonization, heat treatment,testing and other equipment. The current sales have covered the country andmore than 80 countries and regions.

paints mini flow meter

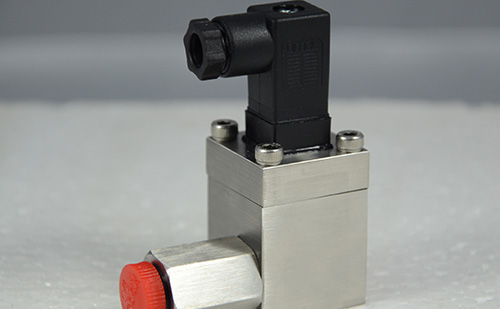

Ovalgear flow meter is widely used inpetroleum, chemical and hydraulic industries due to its advantages of highprecision, simple installation, stable performance and goodrepeatability.However, the Oval gear flow meter that can be produceddomestically can only be applied due to the impatience of high pressure In thelow pressure occasion, the high pressure measurement occasion can only rely onthe foreign imported high pressure flowmeter.Therefore, the research of thehigh pressure Oval gear flow meter will help to expand the domestic applicationof the Oval gear flow meter and promote the development of the domestic flowmeasurement. Deep instrumentation independent research and development of the Ovalgear flow meter pressure up to 1000bar, it can be said has reached a higherlevel in the world, and obtain measurement certificate.

Oval gear flow meter, belonging to a type of volumetric flowmeter,cylindrical shape, with import and export, according to the media with a customfilter. Small size, light weight, easy installation, compact structure, withouttoo much maintenance; other The range ratio is very wide, generally more than1: 100, the minimum flow rate can be measured to 0.3ml / min; and thelinearization accuracy can reach 0.5% FS of full scale, so the use is very wideand can be used for measuring, regulating, controlling and distributing Highand low viscosity, or corrosive liquids, and there are health-type,explosion-proof for a special environment.

paints mini flow meter

val gear rotor. The gearrotor meshes with the rotating shaft to convey the fluid. The permanent magnetarranged in the rotor is used for the detection of the rotor rotation. Twosensor holes are placed on the upper end to cover the detection sensor. Asealing ring is installed between the housing and the upper and lower end capsto prevent leakage of the measurement fluid. The base depth flowmeter is madeof a material with high wear resistance so that the flowmeter Can guaranteehigh precision measurement within the long service life.

paints mini flow meter

Maintechnical data of JSN micro oval Oval gear flow meter

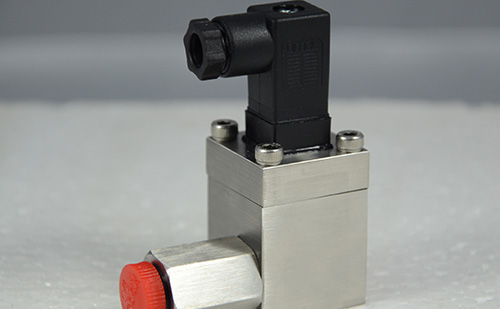

CX-M2,flow range :0.5~150ml/min,accuracy 0.5%,G1/8"

CX-M3, flowrange:3~300ml/min,accuracy 0.5%,G1/8"

CX-M5, flowrange:5~1000ml/min,accuracy 0.5%,G1/8"

CX-M6, flowrange:0.5~100L/H,accuracy 0.5%,G1/4"

CX-M9, flowrange:6~600L/H,accuracy 0.5%,G1/4"

CX-M12,flow range:0.3~30L/Min, accuracy 0.5%,G1/2"

CX-M25,flow range:0.5~100L/Min, accuracy 0.5%,G1"

What are the precautions for the gear flow meter?

1) If the medium temperature is too high, or the pressure is too high, please inform us before purchasing, we can customize it for you.

2) When the pipeline is continuously operated and the flowmeter is to be installed in a horizontal pipeline, a bypass pipeline should be installed to facilitate cleaning and overhaul; when the flowmeter is installed on a vertical pipeline, the flowmeter should be installed on the bypass. In the pipeline, to prevent debris from falling into the instrument. When the fluid flows from bottom to top, the vertical tube in the upper part of the flowmeter should be as short as possible to reduce the precipitation of impurities in the upper piping.