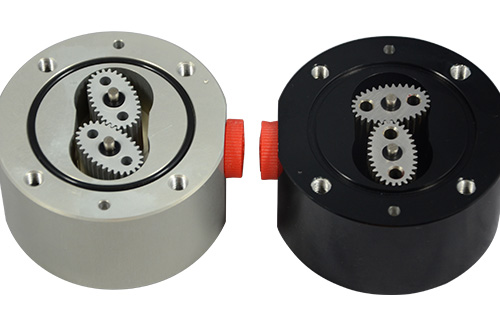

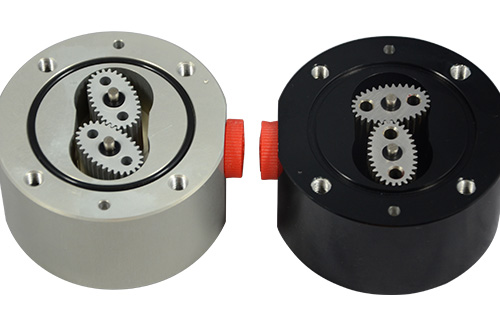

lubracating mini flowmeter

email: porter@microflowmeter.com Shanghai JSN Micro Flow Meter CO.,LTD, research andproduce electromagnetic flow meter, Super Micro Liquid Flow Meter,Ovalgear flow meter ,Mass Flow Meter,Circle Spur Gear Flow Meter,Gear Pump,Gearmetering Pump etc for about 10 years.“JSN trademark and top tenproducts” have won ISO9001, CE, SGS international qualitysystem certification. As the backbone enterprise of China"s automationinstrumentation, it currently supports more than 3,000 companies across thecountry, especially road construction equipment, asphalt mixing stations, roadfuel injection, grouting, polyurethane, dispensing, hot-melt adhesives andother mechanical equipment and automation. Application occasions. Our factoryhas independent CNC machining center, gear carbonization, heat treatment,testing and other equipment. The current sales have covered the country andmore than 80 countries and regions.

lubracating mini flowmeter

At presentdomestic Oval gear flow meter structure is complex, bulky, bulky, noisy, smallscale, not suitable for low viscosity liquid, the market is more common withDTO series and OGM series. For these problems the country has been unable toovercome, while the Shanghai JiShen instrument Instrument company oval gear Ovalgear flow meter does not have the above problems, such as the same DN25caliber, our model CX-M25-AL, flow range: 0.5 ~ 100L / M, range of 1: 200 orhigher, and weighs only 1.5KG , While the DTO-25, the flow of 600-6000L / H,range ratio of only 1:10, the weight of up to 23KG. All this due totechnological breakthroughs, our chief engineer Tu workers, he is a formerSiemens senior engineer, the use of equipment It is also Siemens CNC MachiningCenter with cutting accuracy up to 0.001mm, which ensures that we produce highquality flow meters.

Base deep gear wheel flowmeter on the production of all caliberflowmeters, basically have stock inventory, which in itself shows that thecompany"s funds and sales are good, we dare to do inventory. Hee Oval gear flowmeter has two national inventions, In the process of production qualitycontrol, starting from the beginning of the procurement of raw materials, everyproduction and precision machining links careful examination, each of the Ovalgear flow meter factory must be continuous calibration test. Processinstallation ISO9001 quality management system strictly enforced, the producthas the CE, SGS and other EU certification. Our company has "the qualityof Germany, China"s manufacturing" as the slogan to create a world-classoval gear flow, real automation instrumentation industry Benchmarking business.

lubracating mini flowmeter

Ovalgear flow meter Through the rotation of the gear cavity, through a series ofdeceleration and speed ratio adjustment mechanism, directly connected with theindicator on the instrument panel, and through the mechanical counter for thetotal display. Or remote display is mainly through The decelerated gear drivesthe permanent magnet to rotate so that the contacts of the spring relay (Hallsensor) are closed or opened synchronously at the same rotation frequency asthe permanent magnet, thereby sending one electric pulse to the other displayinstrument.

lubracating mini flowmeter

Maintechnical data of JSN micro oval Oval gear flow meter

CX-M2,flow range :0.5~150ml/min,accuracy 0.5%,G1/8"

CX-M3, flowrange:3~300ml/min,accuracy 0.5%,G1/8"

CX-M5, flowrange:5~1000ml/min,accuracy 0.5%,G1/8"

CX-M6, flowrange:0.5~100L/H,accuracy 0.5%,G1/4"

CX-M9, flowrange:6~600L/H,accuracy 0.5%,G1/4"

CX-M12,flow range:0.3~30L/Min, accuracy 0.5%,G1/2"

CX-M25,flow range:0.5~100L/Min, accuracy 0.5%,G1"

Oval gear flow meter knowledge:As a volumetric flowmeter, the tiny Oval gear flow meter has relatively low requirements for the front and rear straight pipe sections, and basically no straight pipe section requirements. The turbine flowmeter, as a speed flowmeter, has relatively high requirements for the front and rear straight pipe sections, especially for small diameter ones. Turbine flowmeter must be equipped with a corresponding section of straight pipe. Because of different internal structures, turbine flowmeters tend to generate eddy currents if they are installed too close to the bend pipe, affecting the internal impeller and affecting the accuracy of the flowmeter.