lacquering plant mini flow sensor

email: porter@microflowmeter.com Shanghai JSN Micro Flow Meter CO.,LTD is specializedin super micro flow meter,oval gear flow meter ,coriolis mass flowmeter,electromagnetic flow meter,piston flow meter,spur gear flow meter,gearpump,gear metering pump design and R&D. After more than 10 years ofdevelopment, a full-scale flow metering equipment has been formed. JSN has been widely used in the world. Especially in the fields ofchemical fiber, spinning, chemical industry, polyurethane, and dispensing, theautomation requirements for flow meter and gear pump are improved and relied onwork basis,Performance,Equipment structure Development, control technologies,etc. have carried out many researches and achieved certain results.

lacquering plant mini flow sensor

Onceupon a time, China"s manufacturing industry in the world"s processing plant hasalways been the "low quality" representative of the world. Inparticular, the Oval gear flow meter for automatic process control has theadvantages of large volume, large noise, small turndown ratio, , The use ofeasy to leak, instability and so on, leaving customers a headache is that manyproblems in the early stages of product does not appear, and in the event ofafter-sale is very troublesome, bothering money, these are domestic objectiveobjective existence of Oval gear flow meter Therefore, users buy Oval gear flowmeter is like buying lottery tickets, do not know sent to the installation siteOval gear flow meter is a blessing, in a sense, is a matter of course, whilethe base depth meter appeared to solve these problems in one fell swoop.

Whymany customers gradually from the major international brands MAX, OVAL Obar,KRACHT Clarke and other gradually purchased base deep Oval gear flow meter it?Many customers also have questions: why base depth can be reported Oval gearflow meter so good? This stems from our engineers is a former Siemens seniorengineer, the device is also fully adopted Siemens CNC machining center, thecutting height of 0.001mm, to ensure that our flowmeters minimum flow meter canbe measured to 0.1ml / min, which are at home and abroad are Rare, the currentproducts have been awarded the national measurement certificate, and ISO, SGS,CE, after thousands of customers hundreds of conditions medium test, once againwe are very grateful to the recognition of domestic and foreign customers.Attitude, carrying domestic and foreign customers look forward to working hardto make real benchmarking business.

lacquering plant mini flow sensor

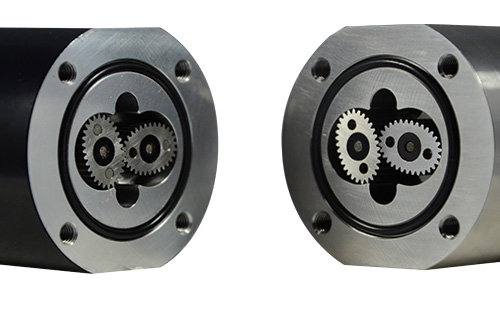

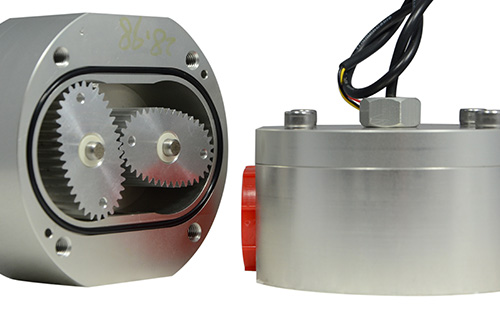

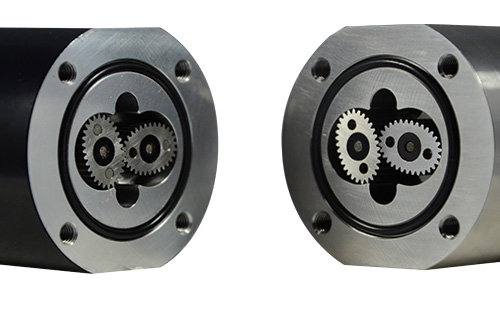

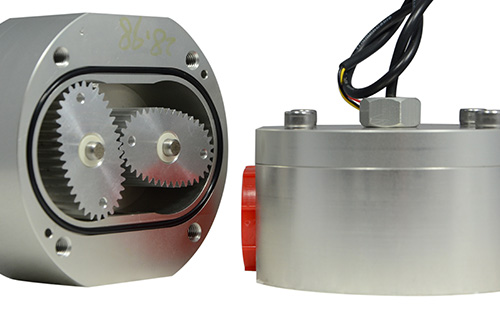

The Ovalgear flow meter is a volumetric flow meter that consists of a flow chamber in achamber and one or several elements that are rotated by fluid flow to form aflow meter. Leakage between the rotating element and the inner wall and theselected working range The internal flow rate is negligible. The rotation ofthe element is transmitted mechanically or by other means to the indicatingdevice to indicate the volume flow of the fluid flowing through.

lacquering plant mini flow sensor

Technicaldata of Gear type flow meter

Model | K-factor | Minimum flow | Flow range | Accuracy |

G0.025 | 0.025ml | 0.001L/Min | 0.008~2L/Min | 0.5% |

G0.04 | 0.04ml | 0.004L/Min | 0.2~4 L/min | 0.5% |

G0.1 | 0.4ml | 0.008L/Min | 0.01~8L/min | 0.5% |

G0.2 | 0.245ml | 0.01L/Min | 0.16~16 L/min | 0.5% |

G0.4 | 0.4ml | 0.01L/Min | 0.16~16 L/min | 0.5% |

G1 | 1.036ml | 0.02L/Min | 0.4~80 L/min | 0.5% |

What are the precautions for the gear flow meter?

1) When the flow exceeds the specified maximum flow rate, the Oval gear flow meter wear increases with the increase of the rotation speed, and the pressure loss increases sharply, should be avoided. Less than the minimum flow, although still able to measure, but the error increases. Flow meter The starting flow is about 2% of the maximum flow, and the normal working flow is preferably 70%-80% of the maximum flow.

2) Deep-rooted flowmeter is used with various viscosity media from 0.3 ~ 100000cps, different viscosity media will affect the range, the following single must be noted

3) The measured liquid temperature should not exceed the specified value, otherwise, the instrument can not work properly, or even stuck, the counter part is easily damaged at high temperatures. Liquid temperature changes will also cause additional errors in viscosity.