hydraulic test stand micro flowmeter

email: porter@microflowmeter.com Shanghai JSN Micro Flow MeterCO.,LTD is established in 2011, directly under Shanghaijurisdiction.Our factory is professional produce electromagnetic flow meter, Super Micro Liquid Flow Meter,Ovalgear flow meter ,Mass Flow Meter,Circle Spur Gear Flow Meter,Gear Pump,Gearmetering Pump etc. After decades of ups and downs, we have established adeep affection with electricity, chemical industry, petroleum, cement, sewage,steel, and environmental protection all over the country. Our factory, as anational key instrumentation production base, has received the ProvincialDepartment of Science and Technology. The leader attaches great importance to,and has received a lot of company leadership acclaim and full affirmation. Atthe same time was rated as high-tech enterprises in Shanghai, and passedIS09001 quality system certification.

hydraulic test stand micro flowmeter

Onceupon a time, China"s manufacturing industry in the world"s processing plant hasalways been the "low quality" representative of the world. Inparticular, the Oval gear flow meter for automatic process control has theadvantages of large volume, large noise, small turndown ratio, , The use ofeasy to leak, instability and so on, leaving customers a headache is that manyproblems in the early stages of product does not appear, and in the event ofafter-sale is very troublesome, bothering money, these are domestic objectiveobjective existence of Oval gear flow meter Therefore, users buy Oval gear flowmeter is like buying lottery tickets, do not know sent to the installation siteOval gear flow meter is a blessing, in a sense, is a matter of course, whilethe base depth meter appeared to solve these problems in one fell swoop.

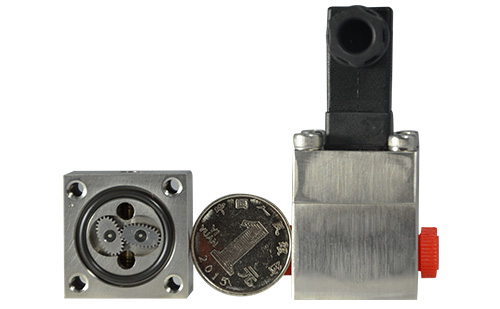

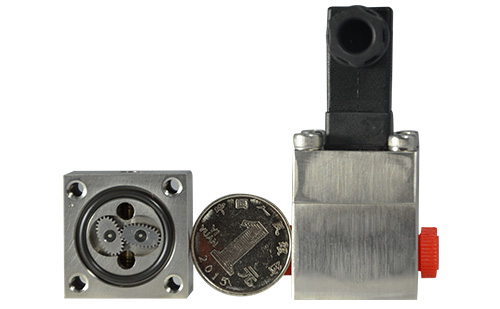

Shanghai JSN Micro Flow Meter Co., Ltd. is the second manufacturer ofmicro Oval gear flow meter in China. It is developed by Tu engineer (formerSiemens senior engineer) with independent intellectual property rights. Theproduction and processing equipment fully adopts Siemens CNC machining centerto ensure the minimum flow 0.1ml / min, which is rare in the world, theaccuracy of over 90% of peers. We can do more temperature 200C, the pressurecan be customized to 1000bar, many customers use it, but also unbelievable.Also domestic Most of the flowmeter use a year after the new calibration, butthe base depth meter after hundreds of conditions of medium test, the servicelife of more than 8 years, and without secondary calibration, since theestablishment of the base depth instrument Instrument determined to beworld-class flow meter, breaking the monopoly of international brands in themirco flow meter industry, so that customers can buy in the country realGerman-made quality flow meter.

hydraulic test stand micro flowmeter

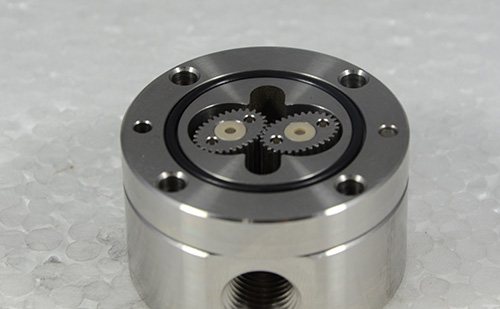

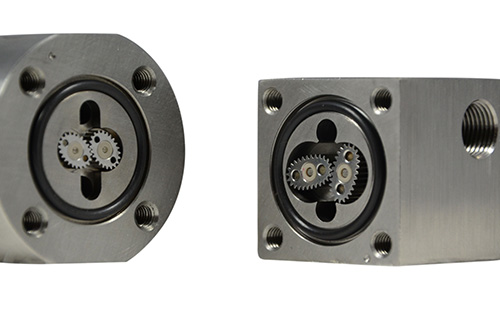

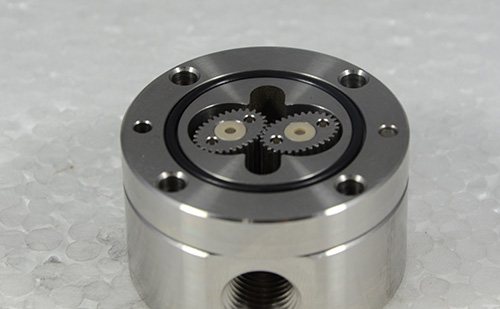

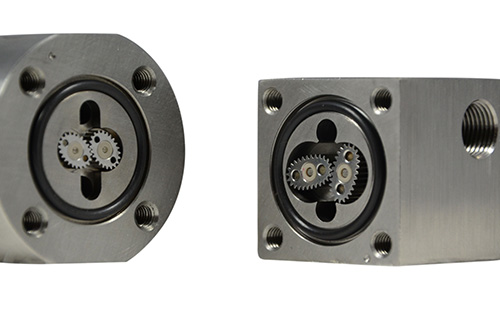

The Ovalgear flow meter consists of a metering box and a pair of gears mounted in themetering box. It forms a sealed initial moon cavity with the upper and lowercover plates as a unit of calculation of the primary displacement. When themeasured liquid enters the flow meter through the pipe, The pressure differencegenerated at the outlet pushes a pair of gears to continuously rotate, and theliquid measured by the initial cavity is continuously delivered to the outlet.The product of the number of rotations of the gear and four times of eachdisplacement is the measured liquid flow rate. The total flowmeter is mainlycomposed of a housing, a counter, a gear and a coupling (magnetic coupling andaxial coupling).

hydraulic test stand micro flowmeter

Technicaldata of Gear type flow meter

Model | K-factor | Minimum flow | Flow range | Accuracy |

G0.025 | 0.025ml | 0.001L/Min | 0.008~2L/Min | 0.5% |

G0.04 | 0.04ml | 0.004L/Min | 0.2~4 L/min | 0.5% |

G0.1 | 0.4ml | 0.008L/Min | 0.01~8L/min | 0.5% |

G0.2 | 0.245ml | 0.01L/Min | 0.16~16 L/min | 0.5% |

G0.4 | 0.4ml | 0.01L/Min | 0.16~16 L/min | 0.5% |

G1 | 1.036ml | 0.02L/Min | 0.4~80 L/min | 0.5% |

What are the precautions for the gear flow meter?

1) If the medium temperature is too high, or the pressure is too high, please inform us before purchasing, we can customize it for you.

2) When the pipeline is continuously operated and the flowmeter is to be installed in a horizontal pipeline, a bypass pipeline should be installed to facilitate cleaning and overhaul; when the flowmeter is installed on a vertical pipeline, the flowmeter should be installed on the bypass. In the pipeline, to prevent debris from falling into the instrument. When the fluid flows from bottom to top, the vertical tube in the upper part of the flowmeter should be as short as possible to reduce the precipitation of impurities in the upper piping.