hydraulic system mini flow sensor

email: porter@microflowmeter.com Shanghai JSN Micro Flow Meter CO.,LTD has a completeplanning, design, research and development, manufacturing, sales, servicesystem, is committed to providing high-quality,high-performance micro flowmeters,ovalgear flow meter ,electromagnetic flow meter,mass flow meter,piston flowmeter,gear flow meter,gear pump,gear metering pump for professional channelcustomers and end customers at home and abroad. Since the 1980s, it has reliedon a strong technical R&D team to focus on the field of flow meter measurement,and developed ultra-miniature, high-precision, high-frequency, high-pressure,and large-scale flow metering equipment. Today, there are more than 500,000units (sets) products are serving all corners of the country and are widelyused in polyurethane, dispensing, hydraulic, odor, petrochemical, power,military, aerospace, scientific research, nuclear industry, cement, metallurgy,steel and other industries.

hydraulic system mini flow sensor

Withthe development of society, the state pays more and more attention to theprocess automation instrumentation industry. However, the Oval gear flow meter industryhas been in a vacancy and has been monopolized by major foreign brands such asMax, KRACHT, OVAL, etc. , People have long endured the expensive, longdelivery, the sale can not be resolved in time and so on, such as semiconductorchip cutting a set of equipment on the millions, once the instrument problems,loss unimaginable, the slayer saw these phenomena, Resolutely resigned assenior engineer in the position of Siemens, the establishment of ShanghaiJi-sheng Instruments Co., Ltd., with great concentration on research anddevelopment of gear flow meter. We have Oval gear flow meter has been awarded anumber of certificates, it is no exaggeration to say that Qishen production Ovalgear flow meter For example, many customers replace the OVAL LSF40 with ourCX-M5-AL because it costs less than half of the LSF40, but has twice the rangethan it does and has the same accuracy.

Whymany customers gradually from the major international brands MAX, OVAL Obar,KRACHT Clarke and other gradually purchased base deep Oval gear flow meter it?Many customers also have questions: why base depth can be reported Oval gearflow meter so good? This stems from our engineers is a former Siemens seniorengineer, the device is also fully adopted Siemens CNC machining center, thecutting height of 0.001mm, to ensure that our flowmeters minimum flow meter canbe measured to 0.1ml / min, which are at home and abroad are Rare, the currentproducts have been awarded the national measurement certificate, and ISO, SGS,CE, after thousands of customers hundreds of conditions medium test, once againwe are very grateful to the recognition of domestic and foreign customers.Attitude, carrying domestic and foreign customers look forward to working hardto make real benchmarking business.

hydraulic system mini flow sensor

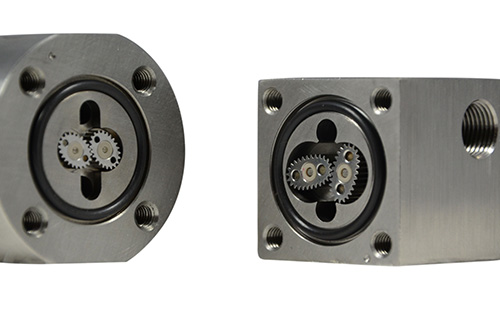

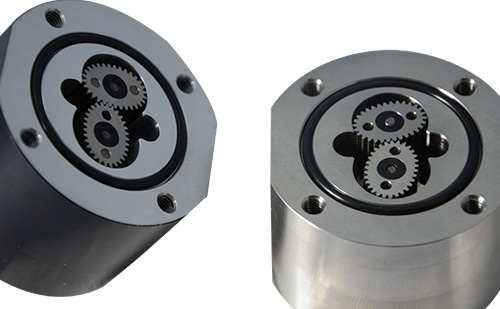

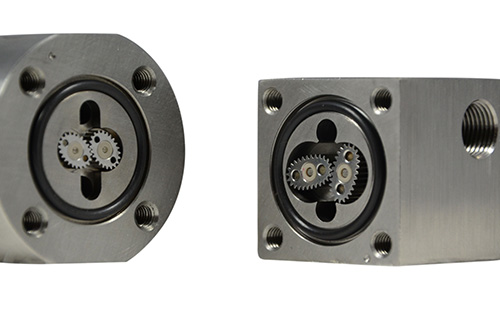

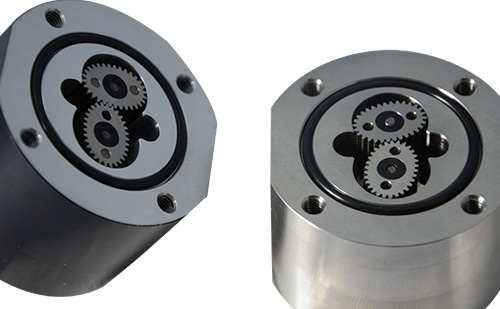

The measuring part of Oval gear flow meter mainly consists of twointermeshing gears and their housings, and the gear generates the acting momentto make it rotate under the pressure difference of the measured medium. Thegears alternately rotate with one another to drive the measured The medium inorder to half the volume of the unit from import to export row by row, so themirco flow meter discharge per revolution measured volume of medium is half thevolume of 4 times the volume flow through the micro-volume flow meter Q Can befigured out

hydraulic system mini flow sensor

Maintechnical data of JSN micro oval Oval gear flow meter

CX-M2,flow range :0.5~150ml/min,accuracy 0.5%,G1/8"

CX-M3, flowrange:3~300ml/min,accuracy 0.5%,G1/8"

CX-M5, flowrange:5~1000ml/min,accuracy 0.5%,G1/8"

CX-M6, flowrange:0.5~100L/H,accuracy 0.5%,G1/4"

CX-M9, flowrange:6~600L/H,accuracy 0.5%,G1/4"

CX-M12,flow range:0.3~30L/Min, accuracy 0.5%,G1/2"

CX-M25,flow range:0.5~100L/Min, accuracy 0.5%,G1"

What are the precautions for the gear flow meter?

1) If the medium temperature is too high, or the pressure is too high, please inform us before purchasing, we can customize it for you.

2) When the pipeline is continuously operated and the flowmeter is to be installed in a horizontal pipeline, a bypass pipeline should be installed to facilitate cleaning and overhaul; when the flowmeter is installed on a vertical pipeline, the flowmeter should be installed on the bypass. In the pipeline, to prevent debris from falling into the instrument. When the fluid flows from bottom to top, the vertical tube in the upper part of the flowmeter should be as short as possible to reduce the precipitation of impurities in the upper piping.