glycol mini flow meter

email: porter@microflowmeter.com ShanghaiJSN Micro Flow Meter CO.,LTD is an automatic meter production R&Denterprise approved by the Chinese government; it is mainly engaged in theresearch, development, and manufacturing of high-end technologies, processesand related equipment in the field of fluid measurement and control to meet theneeds of China and the world for fluid measurement and control equipment. Andthe higher requirements of the products. The company adopts internationaladvanced product design, manufacturing and management technologies, anddevelopment, produce the high quality super micro liquid flow meter,oval gearflow meter ,mass flow meter, circle spur gear flow meter,gear pump,gearmetering pump to meet China and world’s higher requirement. Wenot only has superior high-tech comprehensive capabilities and strict qualitymanagement, measurement management and other systems as well as improvedprocessing and testing methods, but also has a talent team that has madeimportant contributions to the development of flow meters and pumps in Chinaand the world.

glycol mini flow meter

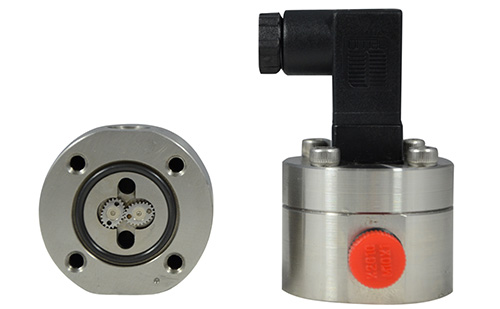

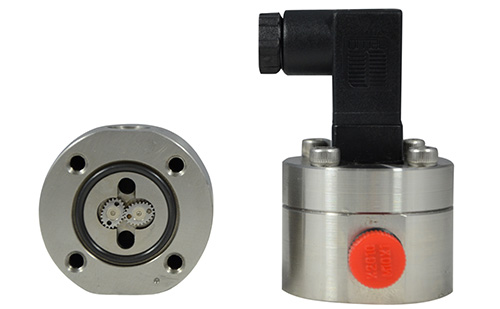

Ovalgear flow meter is widely used inpetroleum, chemical and hydraulic industries due to its advantages of highprecision, simple installation, stable performance and goodrepeatability.However, the Oval gear flow meter that can be produceddomestically can only be applied due to the impatience of high pressure In thelow pressure occasion, the high pressure measurement occasion can only rely onthe foreign imported high pressure flowmeter.Therefore, the research of thehigh pressure Oval gear flow meter will help to expand the domestic applicationof the Oval gear flow meter and promote the development of the domestic flowmeasurement. Deep instrumentation independent research and development of the Ovalgear flow meter pressure up to 1000bar, it can be said has reached a higherlevel in the world, and obtain measurement certificate.

A newgeneration of deep base Oval gear flow meter has been officially listed on thenational market in early 2017. This is a newly developed volumetric flowmeteror a positive displacement flowmeter developed by QWEN engineers combiningadvanced technologies both at home and abroad. Deep base of the exhibitionhall, will see the flow meters on behalf of the generation (such as DTO, CX-FM,CX-M, CX-G series), also see the base depth meter in the continuoustechnological innovation. Is characterized by small flow, a large range, highprecision, long life. Through several iterations, the quality of the product isgetting higher and higher, while the price is less than one-third of the importedbrands, can be said that the Shanghai base deep mirco flow meter Successfuldevelopment, domestic customers do not have to worry about delivery, sale andother issues.

glycol mini flow meter

The ovalgear flow meter"s metering principle is the same as that of a generalvolumetric flow meter. The gears mesh with the fluid to be transported. Thefluid to be measured enters the chamber through the oil inlet and pushes therotor so that the fluid is continuously divided into the same volume of fluid.Oil port output. For every one rotation of the rotor, the flowmeter outputs thesame volume of fluid in the four metering chambers in the figure. By measuringthe number of revolutions of the elliptical gear rotor, the volume flow throughthe fluid can be obtained.

glycol mini flow meter

Technicaldata of Gear type flow meter

Model | K-factor | Minimum flow | Flow range | Accuracy |

G0.025 | 0.025ml | 0.001L/Min | 0.008~2L/Min | 0.5% |

G0.04 | 0.04ml | 0.004L/Min | 0.2~4 L/min | 0.5% |

G0.1 | 0.4ml | 0.008L/Min | 0.01~8L/min | 0.5% |

G0.2 | 0.245ml | 0.01L/Min | 0.16~16 L/min | 0.5% |

G0.4 | 0.4ml | 0.01L/Min | 0.16~16 L/min | 0.5% |

G1 | 1.036ml | 0.02L/Min | 0.4~80 L/min | 0.5% |

What are the precautions for the gear flow meter?

1) If the medium temperature is too high, or the pressure is too high, please inform us before purchasing, we can customize it for you.

2) When the pipeline is continuously operated and the flowmeter is to be installed in a horizontal pipeline, a bypass pipeline should be installed to facilitate cleaning and overhaul; when the flowmeter is installed on a vertical pipeline, the flowmeter should be installed on the bypass. In the pipeline, to prevent debris from falling into the instrument. When the fluid flows from bottom to top, the vertical tube in the upper part of the flowmeter should be as short as possible to reduce the precipitation of impurities in the upper piping.