closed-loop management mini flow meter

email: porter@microflowmeter.com Shanghai JSN Micro Flow Meter CO.,LTD is theprofessional supplier for oval gear flow meter ,mass flow meter,electromagneticflow meter,micro flow meter,gear pump.The products are widely used for Petroleum,petrochemical, chemical, metallurgy, nuclear industry, environmentalprotection, electricity, national defense, medicine, food and other fields, andexported to foreign countries. The company was founded in 2011 by Siemens engineersand has advanced CNC machining centers in the country. Since its inception, thecompany has continued to profit, has developed steadily, has strong technicalequipment and human resources, and has provided a large number of high-qualitymetering products for various industries in the national economy.

closed-loop management mini flow meter

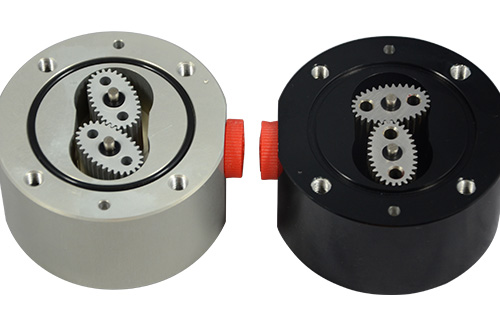

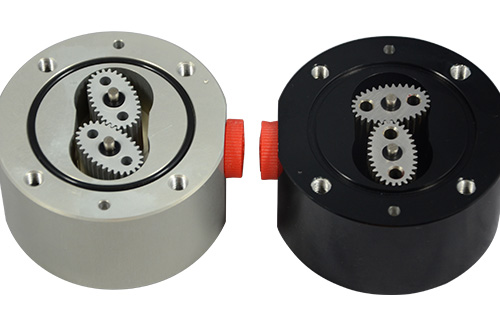

At presentdomestic Oval gear flow meter structure is complex, bulky, bulky, noisy, smallscale, not suitable for low viscosity liquid, the market is more common withDTO series and OGM series. For these problems the country has been unable toovercome, while the Shanghai JiShen instrument Instrument company oval gear Ovalgear flow meter does not have the above problems, such as the same DN25caliber, our model CX-M25-AL, flow range: 0.5 ~ 100L / M, range of 1: 200 orhigher, and weighs only 1.5KG , While the DTO-25, the flow of 600-6000L / H,range ratio of only 1:10, the weight of up to 23KG. All this due totechnological breakthroughs, our chief engineer Tu workers, he is a formerSiemens senior engineer, the use of equipment It is also Siemens CNC MachiningCenter with cutting accuracy up to 0.001mm, which ensures that we produce highquality flow meters.

A newgeneration of deep base Oval gear flow meter has been officially listed on thenational market in early 2017. This is a newly developed volumetric flowmeteror a positive displacement flowmeter developed by QWEN engineers combiningadvanced technologies both at home and abroad. Deep base of the exhibitionhall, will see the flow meters on behalf of the generation (such as DTO, CX-FM,CX-M, CX-G series), also see the base depth meter in the continuoustechnological innovation. Is characterized by small flow, a large range, highprecision, long life. Through several iterations, the quality of the product isgetting higher and higher, while the price is less than one-third of the importedbrands, can be said that the Shanghai base deep mirco flow meter Successfuldevelopment, domestic customers do not have to worry about delivery, sale andother issues.

closed-loop management mini flow meter

Ovalgear flow meter Through the rotation of the gear cavity, through a series ofdeceleration and speed ratio adjustment mechanism, directly connected with theindicator on the instrument panel, and through the mechanical counter for thetotal display. Or remote display is mainly through The decelerated gear drivesthe permanent magnet to rotate so that the contacts of the spring relay (Hallsensor) are closed or opened synchronously at the same rotation frequency asthe permanent magnet, thereby sending one electric pulse to the other displayinstrument.

closed-loop management mini flow meter

Technicaldata of Gear type flow meter

Model | K-factor | Minimum flow | Flow range | Accuracy |

G0.025 | 0.025ml | 0.001L/Min | 0.008~2L/Min | 0.5% |

G0.04 | 0.04ml | 0.004L/Min | 0.2~4 L/min | 0.5% |

G0.1 | 0.4ml | 0.008L/Min | 0.01~8L/min | 0.5% |

G0.2 | 0.245ml | 0.01L/Min | 0.16~16 L/min | 0.5% |

G0.4 | 0.4ml | 0.01L/Min | 0.16~16 L/min | 0.5% |

G1 | 1.036ml | 0.02L/Min | 0.4~80 L/min | 0.5% |

Commonfault causes, troubleshooting

a. Thegear does not rotate: The gear is jammed by debris, the gear and cavity need tobe cleaned, and the filter is cleaned or replaced.

b. Thesmall flow error is too large: The flowmeter is installed in the wrongdirection, the best position goes up and down, or there are impurities to blockthe gear and need to be cleaned.

c. Theflow error is too large: The actual use flow range is less than or far greaterthan the flowmeter range. The corresponding flowmeter must be selected.

d. Noflow sensor signal: The gear is stuck or the circuit is connected incorrectlyor the circuit is damaged. The gear and cavity must be cleaned, or the circuitmust be correctly connected or replaced.