chemicals micro flow measurement

email: porter@microflowmeter.com Shanghai JSN Micro Flow Meter CO.,LTD use advanced scientific managementas a means, relying on Shanghai’s advantages as a key science and educationcity in the country, it has fully utilized resources and actively cooperatedwith Shanghai Jiaotong University, Shanghai’s Fudan University and otheruniversities, and had some achievement, especially in super micro flow,ovalgear flow meter ,coriolis mass flowmeter,electromagnetic flow meter,piston flowmeter,spur gear flow meter,gear pump,gear metering pump. In the past year,ourcompany had establish the reliable and lasting research cooperation with ChineseAcademy of Sciences, Peking University, Norwegian University and other researchinstitutes.Now company is involved in polyurethane, fuel consumption,automotive, dispensing robots, semiconductors, odorizing equipment, batteries,electricity, telecommunications, petroleum, chemical, coal, metallurgy, waterconservancy, food, medical, machinery and other industries. In futuredevelopment, Shanghai JSN should enlarge and strengthen our company, leadinginto the ranks of companies with international competitiveness, and strive tocreate an international, green, sustainable development of instrumentationcompany.

chemicals micro flow measurement

Withthe development of society, the state pays more and more attention to theprocess automation instrumentation industry. However, the Oval gear flow meter industryhas been in a vacancy and has been monopolized by major foreign brands such asMax, KRACHT, OVAL, etc. , People have long endured the expensive, longdelivery, the sale can not be resolved in time and so on, such as semiconductorchip cutting a set of equipment on the millions, once the instrument problems,loss unimaginable, the slayer saw these phenomena, Resolutely resigned assenior engineer in the position of Siemens, the establishment of ShanghaiJi-sheng Instruments Co., Ltd., with great concentration on research anddevelopment of gear flow meter. We have Oval gear flow meter has been awarded anumber of certificates, it is no exaggeration to say that Qishen production Ovalgear flow meter For example, many customers replace the OVAL LSF40 with ourCX-M5-AL because it costs less than half of the LSF40, but has twice the rangethan it does and has the same accuracy.

Ovalgear flow meter is a new type of volumetric flowmeter, in addition to apositive displacement flowmeter with high accuracy, the flow is not sensitiveto other advantages, there are the following advantages: Wide range, usually inthe flow meter is 10: l, and Deep flowmeter is generally 100: 1, or even 1000:1, the accuracy is still above 0.5%, suitable for high pressure flowmeasurement, the maximum pressure can reach 100Mpa, especially suitable for themeasurement of small flow, the minimum measurement limit can be 0.3ml / min ,Less affected by the viscosity characteristics of the medium, suitable for flowmeasurement under various viscosity conditions.

chemicals micro flow measurement

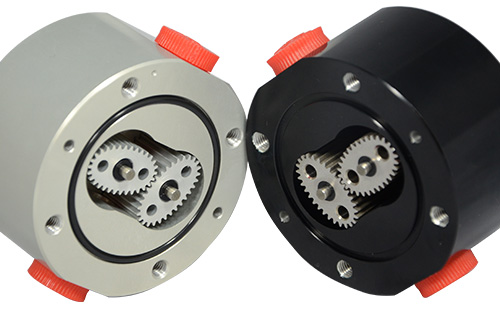

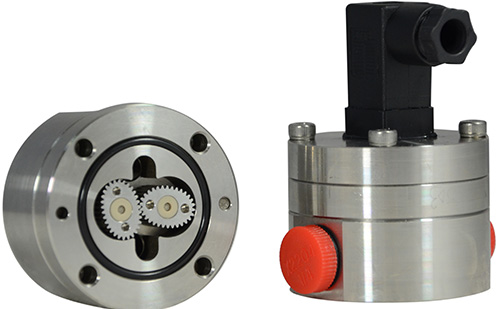

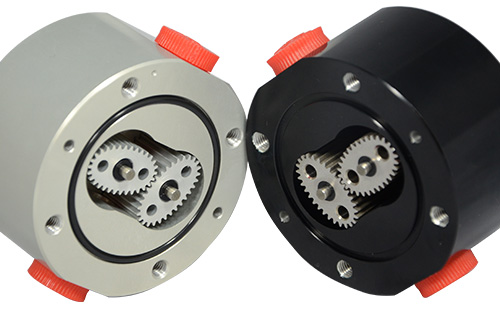

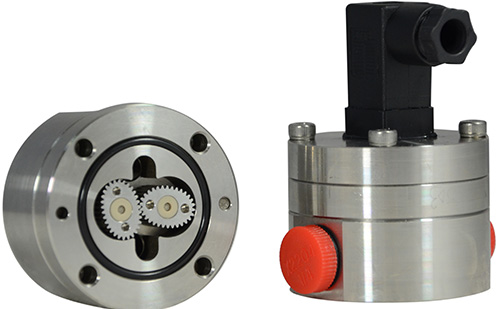

The Ovalgear flow meter is composed of a flow transmitter and a counting mechanism. Themain part of the transmitter consists of a measuring chamber equipped with apair of gear rotors and a sealing coupling. The counting mechanism consists ofa speed reducing mechanism, a precision adjusting mechanism, a counter and apower Pulse transmitter and other components.

chemicals micro flow measurement

Technicaldata of Gear type flow meter

Model | K-factor | Minimum flow | Flow range | Accuracy |

G0.025 | 0.025ml | 0.001L/Min | 0.008~2L/Min | 0.5% |

G0.04 | 0.04ml | 0.004L/Min | 0.2~4 L/min | 0.5% |

G0.1 | 0.4ml | 0.008L/Min | 0.01~8L/min | 0.5% |

G0.2 | 0.245ml | 0.01L/Min | 0.16~16 L/min | 0.5% |

G0.4 | 0.4ml | 0.01L/Min | 0.16~16 L/min | 0.5% |

G1 | 1.036ml | 0.02L/Min | 0.4~80 L/min | 0.5% |

What are the precautions for the gear flow meter?

1) If the medium temperature is too high, or the pressure is too high, please inform us before purchasing, we can customize it for you.

2) When the pipeline is continuously operated and the flowmeter is to be installed in a horizontal pipeline, a bypass pipeline should be installed to facilitate cleaning and overhaul; when the flowmeter is installed on a vertical pipeline, the flowmeter should be installed on the bypass. In the pipeline, to prevent debris from falling into the instrument. When the fluid flows from bottom to top, the vertical tube in the upper part of the flowmeter should be as short as possible to reduce the precipitation of impurities in the upper piping.