brakish water mini flow meter

email: porter@microflowmeter.com Shanghai JSN Micro Flow Meter CO.,LTD is located in industrialzone of Shanghai.Professional research and produce electromagnetic flow meter, Super Micro Liquid Flow Meter,Ovalgear flow meter ,Mass Flow Meter,Circle Spur Gear Flow Meter,Gear Pump,Gearmetering Pump etc. The company integrates scientific research andproduction, draws on the advanced technology experience of the same industry athome and abroad, and based on the concept of “excellence, harmony and win-win”,independently researches and develops a series of gear flow meters, gear pumpproducts, with high quality and low price. As an advantage, it is widely usedin domestic chemical fiber, plastic, polyurethane, fuel injector, dispensingand other industries. The company adhering to the "quality is thefoundation, service is the key, integrity is fundamental, cooperation is awin-win" business philosophy to meet customer demand for Purpose, withquality products, excellent service as a medium, relying on professional, anddomestic and foreign friends to join hands in creating brilliant career.

brakish water mini flow meter

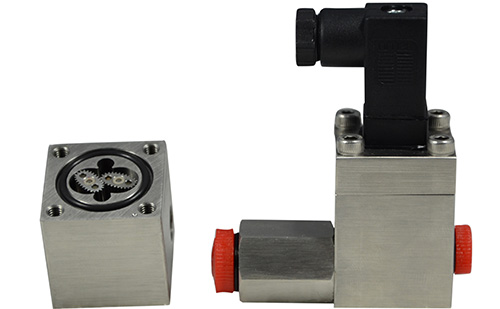

Ovalgear flow meter is widely used inpetroleum, chemical and hydraulic industries due to its advantages of highprecision, simple installation, stable performance and goodrepeatability.However, the Oval gear flow meter that can be produceddomestically can only be applied due to the impatience of high pressure In thelow pressure occasion, the high pressure measurement occasion can only rely onthe foreign imported high pressure flowmeter.Therefore, the research of thehigh pressure Oval gear flow meter will help to expand the domestic applicationof the Oval gear flow meter and promote the development of the domestic flowmeasurement. Deep instrumentation independent research and development of the Ovalgear flow meter pressure up to 1000bar, it can be said has reached a higherlevel in the world, and obtain measurement certificate.

Shanghai JSN Micro Flow Meter Co., Ltd. is the second manufacturer ofmicro Oval gear flow meter in China. It is developed by Tu engineer (formerSiemens senior engineer) with independent intellectual property rights. Theproduction and processing equipment fully adopts Siemens CNC machining centerto ensure the minimum flow 0.1ml / min, which is rare in the world, theaccuracy of over 90% of peers. We can do more temperature 200C, the pressurecan be customized to 1000bar, many customers use it, but also unbelievable.Also domestic Most of the flowmeter use a year after the new calibration, butthe base depth meter after hundreds of conditions of medium test, the servicelife of more than 8 years, and without secondary calibration, since theestablishment of the base depth instrument Instrument determined to beworld-class flow meter, breaking the monopoly of international brands in themirco flow meter industry, so that customers can buy in the country realGerman-made quality flow meter.

brakish water mini flow meter

val gear rotor. The gearrotor meshes with the rotating shaft to convey the fluid. The permanent magnetarranged in the rotor is used for the detection of the rotor rotation. Twosensor holes are placed on the upper end to cover the detection sensor. Asealing ring is installed between the housing and the upper and lower end capsto prevent leakage of the measurement fluid. The base depth flowmeter is madeof a material with high wear resistance so that the flowmeter Can guaranteehigh precision measurement within the long service life.

brakish water mini flow meter

Technicaldata of CX-M Series micro oval Oval gear flow meter

Model | Flow range | Accuracy | Connection size |

CX-M2 | 0.5~150ml/min | 0.5% | G1/8" |

CX-M3 | 3~300ml/min | 0.5% | G1/8" |

CX-M5 | 5~1000ml/min | 0.5% | G1/8" |

CX-M6 | 0.5~100L/H | 0.5% | G1/4" |

CX-M9 | 6~600L/H | 0.5% | G1/4" |

CX-M12 | 0.3~30L/Min | 0.5% | G1/2" |

CX-M25 | 0.5~100L/Min | 0.5% | G1" |

What"s the reason for the tiny gear flow meter"s wheels not turning? the reason:1. The filter is clogged.2. Impurities enter the flowmeter and the rotor gets stuck.Treatment measures:1. Clean the filter.2. Check the filter for damage and clean the inside of the flow meter.