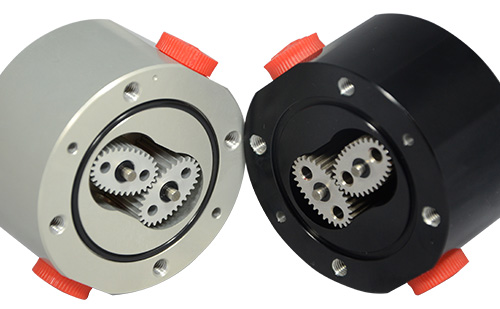

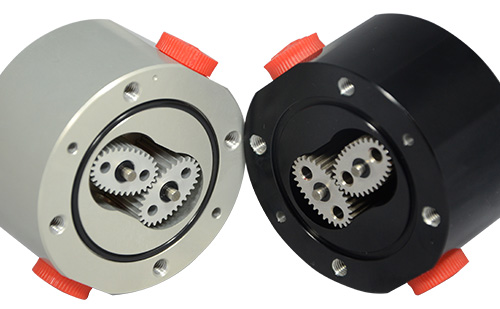

CYLINDRICAL OIL mini flow meter

email: porter@microflowmeter.com Shanghai JSN Micro Flow Meter CO.,LTD use advanced scientific managementas a means, relying on Shanghai’s advantages as a key science and educationcity in the country, it has fully utilized resources and actively cooperatedwith Shanghai Jiaotong University, Shanghai’s Fudan University and otheruniversities, and had some achievement, especially in super micro flow,ovalgear flow meter ,coriolis mass flowmeter,electromagnetic flow meter,piston flowmeter,spur gear flow meter,gear pump,gear metering pump. In the past year,ourcompany had establish the reliable and lasting research cooperation with ChineseAcademy of Sciences, Peking University, Norwegian University and other researchinstitutes.Now company is involved in polyurethane, fuel consumption,automotive, dispensing robots, semiconductors, odorizing equipment, batteries,electricity, telecommunications, petroleum, chemical, coal, metallurgy, waterconservancy, food, medical, machinery and other industries. In futuredevelopment, Shanghai JSN should enlarge and strengthen our company, leadinginto the ranks of companies with international competitiveness, and strive tocreate an international, green, sustainable development of instrumentationcompany.

CYLINDRICAL OIL mini flow meter

Ovalgear flow meter is widely used inpetroleum, chemical and hydraulic industries due to its advantages of highprecision, simple installation, stable performance and goodrepeatability.However, the Oval gear flow meter that can be produceddomestically can only be applied due to the impatience of high pressure In thelow pressure occasion, the high pressure measurement occasion can only rely onthe foreign imported high pressure flowmeter.Therefore, the research of thehigh pressure Oval gear flow meter will help to expand the domestic applicationof the Oval gear flow meter and promote the development of the domestic flowmeasurement. Deep instrumentation independent research and development of the Ovalgear flow meter pressure up to 1000bar, it can be said has reached a higherlevel in the world, and obtain measurement certificate.

Oval gear flow meter, belonging to a type of volumetric flowmeter,cylindrical shape, with import and export, according to the media with a customfilter. Small size, light weight, easy installation, compact structure, withouttoo much maintenance; other The range ratio is very wide, generally more than1: 100, the minimum flow rate can be measured to 0.3ml / min; and thelinearization accuracy can reach 0.5% FS of full scale, so the use is very wideand can be used for measuring, regulating, controlling and distributing Highand low viscosity, or corrosive liquids, and there are health-type,explosion-proof for a special environment.

CYLINDRICAL OIL mini flow meter

The Ovalgear flow meter is a volumetric flow meter that consists of a flow chamber in achamber and one or several elements that are rotated by fluid flow to form aflow meter. Leakage between the rotating element and the inner wall and theselected working range The internal flow rate is negligible. The rotation ofthe element is transmitted mechanically or by other means to the indicatingdevice to indicate the volume flow of the fluid flowing through.

CYLINDRICAL OIL mini flow meter

Technicaldata of CX-M Series micro oval Oval gear flow meter

Model | Flow range | Accuracy | Connection size |

CX-M2 | 0.5~150ml/min | 0.5% | G1/8" |

CX-M3 | 3~300ml/min | 0.5% | G1/8" |

CX-M5 | 5~1000ml/min | 0.5% | G1/8" |

CX-M6 | 0.5~100L/H | 0.5% | G1/4" |

CX-M9 | 6~600L/H | 0.5% | G1/4" |

CX-M12 | 0.3~30L/Min | 0.5% | G1/2" |

CX-M25 | 0.5~100L/Min | 0.5% | G1" |

Oval gear flow meter knowledge:As a volumetric flowmeter, the tiny Oval gear flow meter has relatively low requirements for the front and rear straight pipe sections, and basically no straight pipe section requirements. The turbine flowmeter, as a speed flowmeter, has relatively high requirements for the front and rear straight pipe sections, especially for small diameter ones. Turbine flowmeter must be equipped with a corresponding section of straight pipe. Because of different internal structures, turbine flowmeters tend to generate eddy currents if they are installed too close to the bend pipe, affecting the internal impeller and affecting the accuracy of the flowmeter.