CYLINDRICAL OIL micro flow measurement

email: porter@microflowmeter.com Shanghai JSN Micro Flow Meter CO.,LTD since we producemicro flow meter,mass flow meter,piston flow meter,electromagnetic flowmeter,oval gear flow meter,gear pump,gear metering pump,we accumulated richexperience for the flow metering equipment. The company policy is base oncontinuous research and development, which enables the company to manufacturehigh-tech and high-efficiency products. With excellent productreliability, these products are carefully selected through the carefulselection of raw materials and components, during the entire machining process,each part is carefully examined, and finally assembled with skilled experience.Before commissioning, every product has appeared in front of customers with highquality.

CYLINDRICAL OIL micro flow measurement

Ovalgear flow meter is widely used inpetroleum, chemical and hydraulic industries due to its advantages of highprecision, simple installation, stable performance and goodrepeatability.However, the Oval gear flow meter that can be produceddomestically can only be applied due to the impatience of high pressure In thelow pressure occasion, the high pressure measurement occasion can only rely onthe foreign imported high pressure flowmeter.Therefore, the research of thehigh pressure Oval gear flow meter will help to expand the domestic applicationof the Oval gear flow meter and promote the development of the domestic flowmeasurement. Deep instrumentation independent research and development of the Ovalgear flow meter pressure up to 1000bar, it can be said has reached a higherlevel in the world, and obtain measurement certificate.

Shanghai JSN Micro Flow Meter Co., Ltd. is the second manufacturer ofmicro Oval gear flow meter in China. It is developed by Tu engineer (formerSiemens senior engineer) with independent intellectual property rights. Theproduction and processing equipment fully adopts Siemens CNC machining centerto ensure the minimum flow 0.1ml / min, which is rare in the world, theaccuracy of over 90% of peers. We can do more temperature 200C, the pressurecan be customized to 1000bar, many customers use it, but also unbelievable.Also domestic Most of the flowmeter use a year after the new calibration, butthe base depth meter after hundreds of conditions of medium test, the servicelife of more than 8 years, and without secondary calibration, since theestablishment of the base depth instrument Instrument determined to beworld-class flow meter, breaking the monopoly of international brands in themirco flow meter industry, so that customers can buy in the country realGerman-made quality flow meter.

CYLINDRICAL OIL micro flow measurement

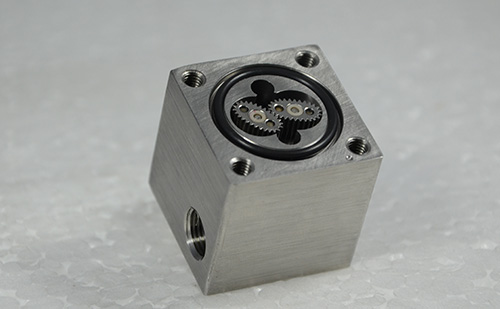

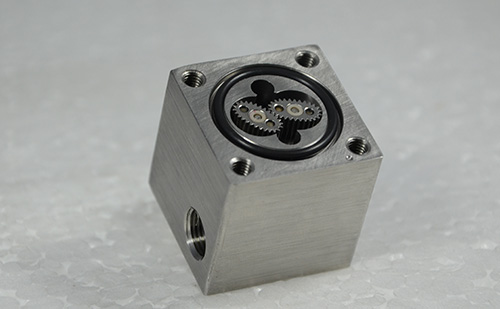

The measuring part of Oval gear flow meter mainly consists of twointermeshing gears and their housings, and the gear generates the acting momentto make it rotate under the pressure difference of the measured medium. Thegears alternately rotate with one another to drive the measured The medium inorder to half the volume of the unit from import to export row by row, so themirco flow meter discharge per revolution measured volume of medium is half thevolume of 4 times the volume flow through the micro-volume flow meter Q Can befigured out

CYLINDRICAL OIL micro flow measurement

Maintechnical data of JSN micro oval Oval gear flow meter

CX-M2,flow range :0.5~150ml/min,accuracy 0.5%,G1/8"

CX-M3, flowrange:3~300ml/min,accuracy 0.5%,G1/8"

CX-M5, flowrange:5~1000ml/min,accuracy 0.5%,G1/8"

CX-M6, flowrange:0.5~100L/H,accuracy 0.5%,G1/4"

CX-M9, flowrange:6~600L/H,accuracy 0.5%,G1/4"

CX-M12,flow range:0.3~30L/Min, accuracy 0.5%,G1/2"

CX-M25,flow range:0.5~100L/Min, accuracy 0.5%,G1"

What are the precautions for the gear flow meter?

1) In the field installation, it should be noted that the direction of the arrow on the flow meter housing is consistent with the flow direction of the fluid;

2) The flowmeter is installed on the same pipe with the same nominal internal diameter as the inlet and outlet fittings. When the pipe is connected with the flowmeter, the seal should not protrude into the fluid;

3) The fluid to be measured shall be filled with the metering room of the flowmeter and the connecting pipes before and after it. If the fluid to be measured contains gas, a gas separator shall be installed before the flowmeter and the filter;